Dream Buy: VW Bus-Based Cherry Picker

An automotive curio that could scarcely be matched...

An Unusual Request

It was a particularly unremarkable Sunday morning, and my mother was gazing out the window at our backyard full of valley oaks, with some being in need of a trim.

“Do you think you could find me a vintage bucket truck?”, she asked, between sips of coffee. “It would be neat if we had our own cherry picker to trim the trees, and maybe to help with decorating the house for Christmas and Halloween.”

My initial reaction was ambivalence: On the one hand, a working, vintage bucket truck would be a killer automotive curio for the family collection. On the other hand, my inner lizard brain--that little voice in one’s head, probably a product of evolution, which tells us not to do things that may kill us--told me that the words “vintage” and “industrial heavy machinery” probably shouldn’t go together. Still, my curiosity for what I might be able to dig up fitting that description got the better of me, and I began looking into industrial trucks of the old-school variety.

I wasn’t sure when the first bucket truck was invented, let alone widely available. What was I even hoping to find? Ever the amateur automotive private-eye, I started out with a simple survey of workhorse vehicles from the last century. Most of the bucket trucks I initially found were from the 70’s and beyond. We’re talking industrial flatbeds based on the Ford F600 and GMC 5000. This was non-ideal, both for aesthetic and practical reasons.

Aesthetically, trucks from the 1960’s and earlier retained a small footprint by today’s standards. (Double cabs and extended wheelbases became more common in the 70’s and 80’s, and trucks have mostly grown larger ever since.) I like the look of a small truck, and they're generally much easier to maneuver. Practically speaking, the car will eventually need to be registered in California. So, whatever I end up with would either have to be pre-1972, or completely flawless smog-wise, in order to comply with regulations enforced by the California Air Resource Board.

Though an F600 would be larger than I was hoping for, my experience working on vintage American cars (and my personal biases favoring Ford) pointed me in that direction. I searched far and wide for a decent F600 with an attached bucket. I quickly found nothing at all, and realized that this wasn’t going to be as easy as finding an old farm truck.

Expanding my horizons, I began to use other search terms to find an old truck with some kind of industrial-grade lift in the rear: “telephone company truck,” “cherry picker,” “aerial lift”, and even “fire engine.” I believe it was a “telephone truck” query which yielded an amazing vehicle that was not only adorable but for sale!

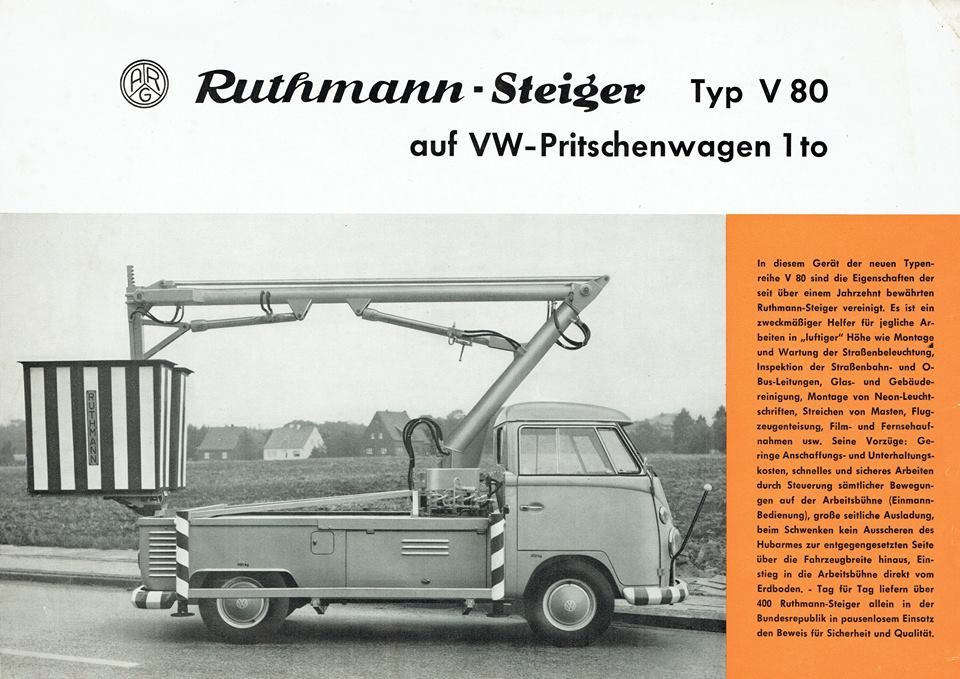

The Volkswagen V 80

The orange brute pictured here is a restored, single cab, truck version of the VW Bus, complete with a functioning Ruthmann-Steiger cherry picker/bucket lift bed. I found it posted on Facebook Marketplace, with an asking price of nearly $40,000.

According to the seller's description, the vehicle is a 1970 VW T2 that was imported from France and is now owned by a collector. When it was still in service, the truck was used by a French telecoms company for field work on telephone poles. The hydraulically-lifted Ruthmann-Steiger bucket arm comes attached to candy-striped stabilizing feet to support it during operation, much like a high-rise construction crane would have. The listing claims the lift is capable of extending as high as 10 meters (or nearly 33 feet in American money) which seems mightily ambitious to me.

The listing also claims that this is an original Ruthmann truck. Though I don’t know exactly what gives that away, I’m sure there are scores of people who would. This is because, as most car people understand, the vintage VW community refuses to die. Enthusiast clubs and websites have kept the public’s passion for Volkswagen’s buses and beetles alive for decades.

Nowadays, even the workhorse VWs get to share the love. I was pleasantly surprised to find a time-capsule website dedicated to the most industrial VWs in the company’s vintage lineup, called DropGates.com. The main focus of the site is on “drop gate” VW pickup trucks, which often served as a foundation for industrial european trucks of the day. I was delighted to find that the site not only had a section dedicated to cherry pickers, but even had some images of the original brochure for the VW Pritschenwagen mit hydraulischer Hebebühne, or “VW Platform Truck with hydraulic lift.” (I have included the brochure and its accompanying translation in the gallery at the end of this article).

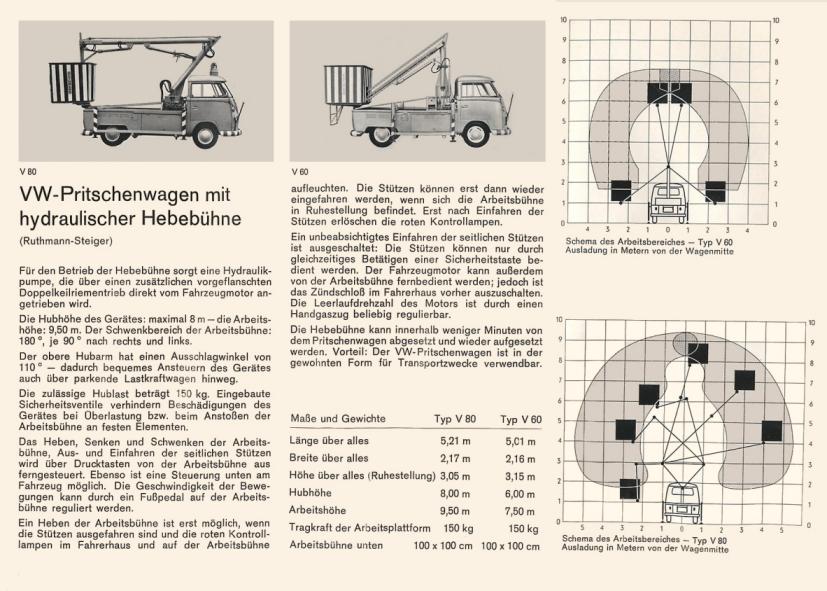

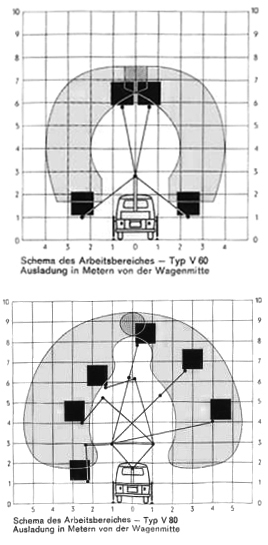

Two versions of the Pritschenwagen with lift were offered: the V 80 and the V 60. The differences between the two versions are minor, with the main differentiator being the attached lift. The V 80 sported a hydraulic lift with a “working height” of 9.5 meters, while the V 60’s lift was quoted at a mere 7.5 meters. (That’s a difference of about six feet, for those of you who forgot your calculators).

I’m pretty blown away by the engineering here, presuming the things actually stay upright during use. The brochure boasts quite a few features, starting with the carrying capacity. The bucket is good for lifting up to 150 kg (or 330 lbs), which is more than enough for your average telecoms worker (or Halloween decorator). The brochures also mentions that the truck has built-in safety valves and mechanical locking features to prevent any danger to workers or damage to equipment during operation. Between all that thoughtful engineering and the included extendable stabilizing supports, I’m sure the bucket is actually a pretty safe place to be. (Provided that the hydraulics have been refurbished and maintained.

While the $40,000 price tag will probably keep me and my kinship out of the particular Pritschenwagen I found, I got a helluva kick out of learning all about them and getting to understand the passion other people still have for these old mules. Unfortunately, a “helluva kick” doesn’t help me hang Christmas lights, so my quest for the perfect bucket truck must go on...

Gallery

Here's a V 80 from Emmerting, Germany. It's easy to tell it's a V 80 because of the three-piece arm. (V 60's only have a two-piece). (Image from TheSamba.com)

Another V 80, at full lift height (9.5 m). (Image from Do You Like Vintage?)

This is one of those F600 bucket trucks I trucks I mentioned. This image comes from a postcard advertisment for a Pennsylvanian painter's company. (Image from HipPostcard.com)

A truck being used by United Illuminating (a regional electricity company in Connecticut) engineers in the field, circa 1961. (Image from United Illuminating on Twitter)

The V 80 Brochure. "This device from the new V 80 series combines the properties of the Ruthmann Steiger, which has been tried and tested for over a decade. It is a useful helper for any work at "lofty" heights such as assembly and maintenance of street lighting, inspection of tram and trolleybus lines, glass and building cleaning, installation of neon signs, painting of masts, aircraft de-icing, film and television recordings, etc. Its advantages: Low acquisition and maintenance costs, fast and safe work by controlling all movements on the work platform (one-man operation), large lateral overhang, when swiveling the lift arm does not swing out to the opposite side beyond the vehicle width, entry into the working platform directly from the ground. - Day after day, more than 400 Ruthmann Steigers in Germany alone, in non-stop work, provide evidence of safety and quality." (Image by DropGates.com, translation by Google).

The V 80 Brochure, cont'd. "The lift is operated by a hydraulic pump that is driven directly by the vehicle engine via an additional pre-flanged double V-belt drive. The lifting height of the device: maximum 8 m - the working height: 9.50 m. The swivel range of the work platform: 180 degrees, 90 to the right and left. The upper lifting arm has a deflection angle of 110 - this makes it easy to control the device even when the truck is parked. The permissible lifting load is 150 kg. Built-in safety valves prevent damage to the device if the work platform is overloaded or if it hits fixed elements. The lifting, lowering and swiveling of the work platform and the extension and retraction of the side supports are remotely controlled via push buttons on the work platform. Control at the bottom of the vehicle is also possible. The speed of the movements can be regulated by a foot pedal on the work platform. The working platform can only be lifted when the supports are extended and the red control lamps in the driver's cab and on the working platform light up. The supports can only be retracted when the working platform is in the rest position. The red control lamps only go out after the supports have been retracted. Unintentional retraction of the side supports is eliminated: The supports can only be operated by pressing a safety button at the same time. The vehicle engine can also be operated remotely from the work platform; however, the ignition lock in the driver's cab must be switched off beforehand. The idling speed of the engine can be regulated as required by a hand throttle. The lift can be set down from the flatbed truck and put back on again within a few minutes. Advantage: The VW flatbed truck can be used in the usual form for transport purposes." (Image by DropGates.com, translation by Google).